Reveal the magic of color shrink film

With the increasing demand for product appearance, the packaging industry has also ushered in new changes. As a new type of packaging material with both beauty and practicality, color shrink film is gradually occupying the dominant position in the market.

Its main component is a highly malleable polyolefin resin. After being made into a film by an advanced blow molding process, it can present a variety of colors and high transparency. Not only that, these materials also have good environmental performance and make a positive contribution to reducing plastic pollution.

Technical Support Behind Colorful Packaging

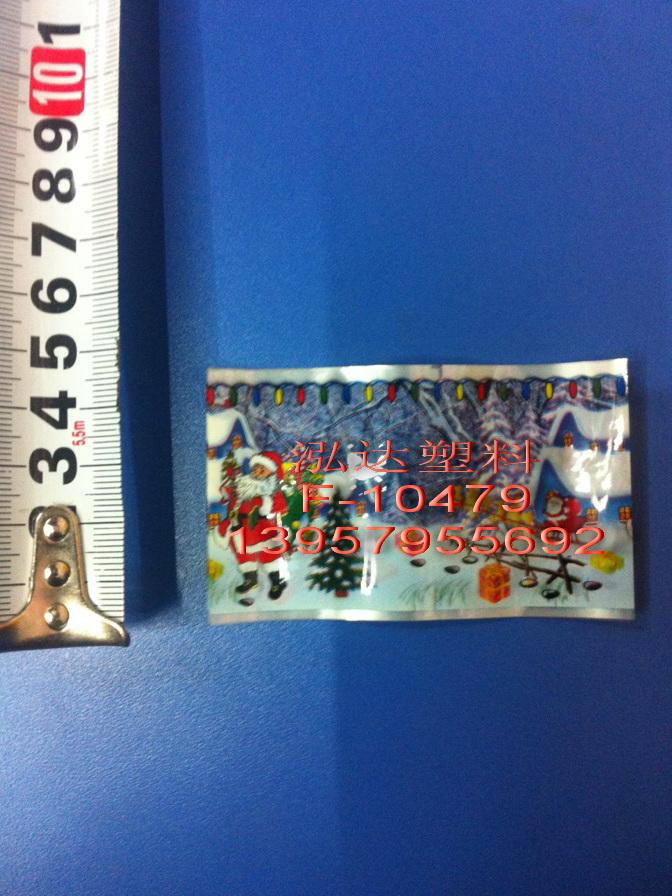

The development of modern technology has greatly improved the quality level of color shrink film. Through sophisticated digital printing equipment, complex patterns can be accurately transferred to the film surface, so that every detail can be vividly displayed.

In addition, the effective control of the heat shrinkage ratio is also the key to ensure the regular shape of the final product. Only when the parameters reach the optimal equilibrium state, can we give full play to the new possibilities of packaging given by technology.

Wide range of packaging solutions

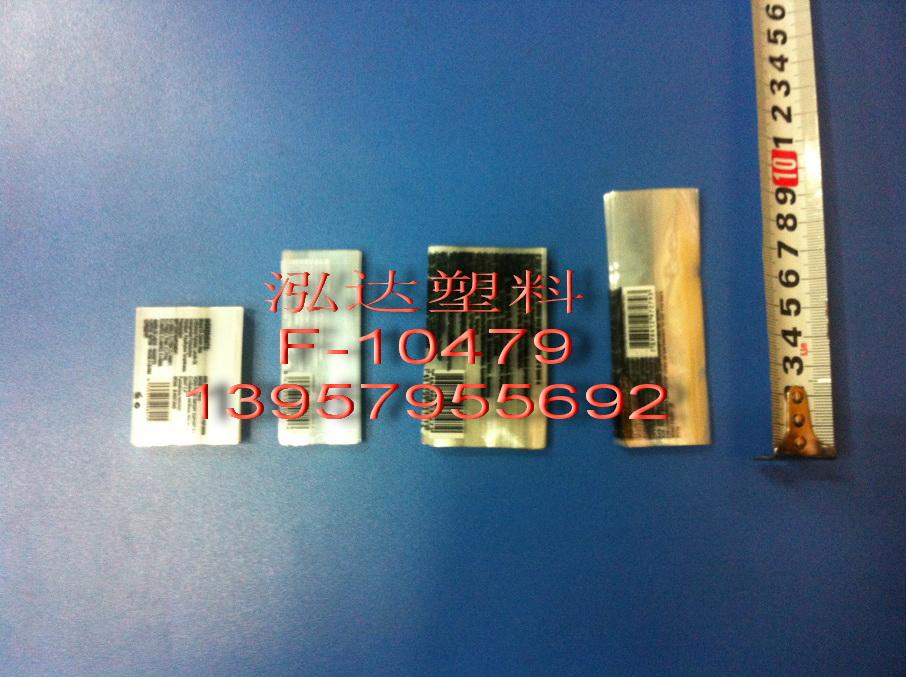

From the exquisite wine bottle packaging in the food and beverage industry to the high-end perfume protection in the cosmetics field, to the small box design of electronic product accessories... Color shrink film can be found in almost every field. For example, a well-known brand of red wine uses this new material to add luxury to its limited edition series; an internationally renowned skin care brand uses holographic reflective coatings to enhance product recognition.

The reason why it is so popular is that it can flexibly adjust the size and thickness according to customer needs and even add functional modules such as anti-counterfeiting labels to meet the special requirements of specific occasions.

Guide to choosing the best color shrink film for you

In the face of a wide range of choices in the market, how to determine which one is the most suitable for your business? First of all, you need to clarify a few basic parameters, such as the required coverage area, the overall effect you expect to achieve, and the cost budget.

Secondly, we should also consider the subtle differences between different types, such as some models may pay more attention to tensile strength but relatively high price; others may focus on flexibility and are suitable for use as an internal buffer layer. Finally, don't forget to estimate whether it is cost-effective in the long run, after all, reasonable planning of the initial investment will help to get more returns later!

Looking to the Future-Color Leads the Change of Packaging Trends

Looking back at the evolution of the past few years at the current point in time, it is not difficult to find that every technological innovation will bring a new round of growth opportunities. It is expected that in the next three to five years, with the continuous emergence of emerging consumer groups and the acceleration of globalization and other factors, the entire industry will usher in a larger wave of upgrading.

The popularization of intelligent production equipment and the improvement of highly customized service capabilities will surely open a new chapter. Let's wait and see! Maybe it won't be long before we see more amazing works being born here.