Strong sealing and good moisture resistance

Color shrink film stands out in the market for its excellent sealing and moisture resistance. This film is made of high-quality polyethylene (PE) material with excellent physical and chemical properties. Under various environmental conditions, the color shrink film can maintain good sealing performance and prevent moisture penetration, thereby protecting the internal products from external factors. Through laboratory testing and user feedback, the color shrink film performs well in practical applications, is reliable and stable.

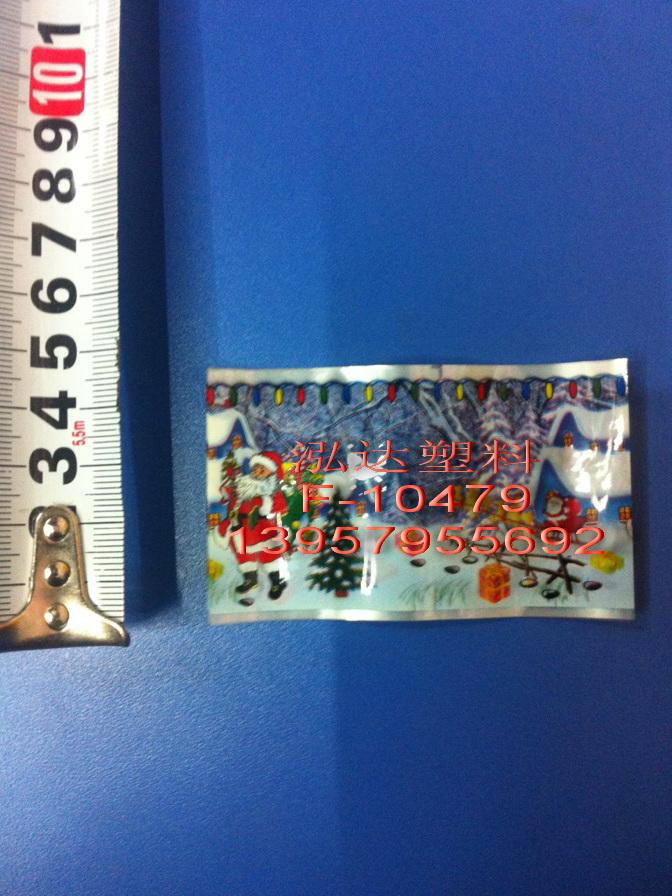

Rich color selection

One of the highlights of the color shrink film is its rich color selection. In addition to the common basic colors such as red, blue, green and yellow, specific colors can also be customized according to customer needs. These colorful films not only enhance the visual effect of the product, but also enhance the brand recognition. Through high-definition pictures and practical application scenes, you can intuitively feel the different effects brought by each color.

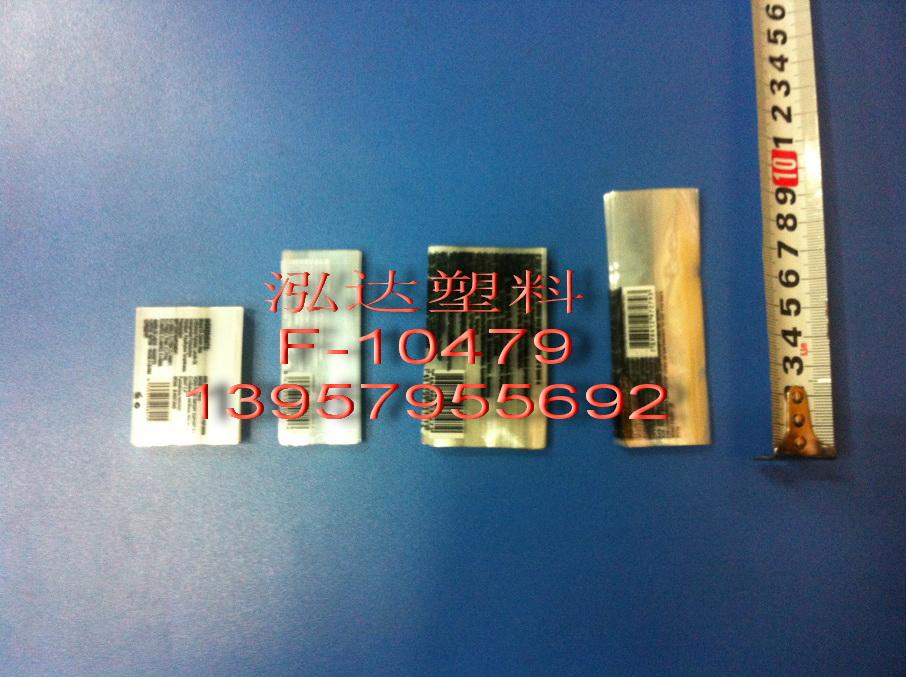

Wide range of applications

Color shrink film has a wide range of applications in many industries, including food, beverages, cosmetics and electronics. In the food industry, color shrink film can effectively protect the freshness and safety of food; in the beverage industry, it can help the product remain intact during transportation; in the cosmetics industry, color shrink film can enhance the high-end sense of the product. Through specific cases and success stories, we can see the practical application effect and customer satisfaction of color shrink film in different fields.

Production process and quality control

The production process of color shrink film involves several key steps, including raw material selection, mixing, extrusion, and cooling. Every step is carried out in strict accordance with international standards to ensure the high quality of the products. Enterprises implement strict quality inspection procedures in the production process. From raw materials to finished products, each batch of products must undergo multiple inspections to ensure that their performance and quality meet the requirements.

Usage and Precautions

The correct use of color shrink film is the key to ensuring its effect. First, it is necessary to put the film on the product to be packaged, and then use a heat gun or a heat shrink machine to heat the film to make the film close to the surface of the product. During use, you need to pay attention to safety matters, such as avoiding excessive temperature and improper operation. In addition, regular maintenance and maintenance of the equipment is also essential to ensure its normal operation.

Improve product packaging quality

Through actual cases and user feedback, it can be seen that color shrink film has a significant effect on improving product packaging quality. It can not only enhance the protection ability of the product, but also improve the appearance of the product and enhance the brand image. For example, after a well-known beverage company used color shrink film, the overall packaging effect of its products has been significantly improved, the market response has been enthusiastic, and sales have also increased.

Environmental Protection and Sustainability

Color shrink film also has obvious advantages in environmental protection and sustainability. The material has good recyclability and can be recycled many times, reducing the waste of resources. At the same time, the energy consumption in the production process is low, in line with the concept of green environmental protection. Its positive contribution to environmental protection can be further verified through data and research reports from authoritative institutions.

Cost-benefit analysis

A detailed cost-benefit analysis shows that color shrink film has obvious cost advantages over other packaging materials. Although the initial investment may be slightly higher, it performs well in reducing packaging costs, improving production efficiency and increasing profit margins. Through the actual data and user cases, we can see the economic benefits of color shrink film for enterprises.

FAQ

Q: Is the color shrink film resistant to high temperatures?

Answer: The color shrink film has a certain high temperature resistance and will not be affected when used in an appropriate temperature range. However, deformation may occur at extreme high temperatures, so it is recommended to understand its temperature resistance range in detail before use.

Q: How to choose the right thickness?

Answer: Choosing the right thickness depends on your specific needs. In general, thinner films are suitable for small lightweight items, while thicker films are more suitable for heavy or fragile items. It is recommended to choose the most suitable thickness according to the characteristics of the product and the use environment.

Limited Time Offers and Promotions

Currently, we are carrying out a series of promotional activities, including discount prices, buy-to-let activities and exclusive benefits for members.