In this era of pursuit of personalization, consumers' first impression of a product often comes from its appearance. As a bridge between brand image and consumers, the importance of packaging can not be ignored. Today we want to introduce the protagonist-color shrink film, it is an indispensable member of this field.

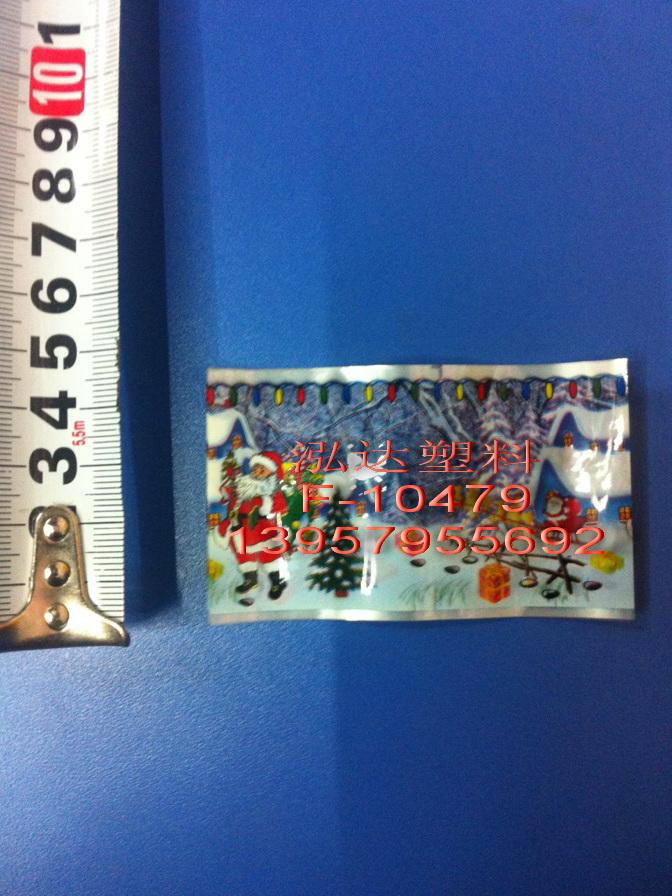

From ordinary transparent film to today's colorful design, color shrink film redefines the artistry of packaging with its unique beauty. It can not only achieve rich color changes, but also has extremely high gloss and clarity, so that every detail can be perfectly presented. This material can closely fit the surface of products of various shapes, whether it is a complex bottle body or a regular box, it can show a refined effect like tailor-made.

So what makes such a performance? The answer lies in its advanced production process and technical support. Color shrink film is made of high quality polyolefin resin, combined with precise control of the heating process so that the film body has a strong heat shrinkage capacity and tear strength. At the same time, in order to meet individual needs, multi-layer composite treatment or special additives can be added to increase functional properties such as barrier and weather resistance.

With the growing market demand, color shrink film has been widely used in beverages, cosmetics, electronic products and other industries.

for example, in the alcoholic beverage industry, a brand logo with great visual impact can be formed by carefully designing the pattern, printing it on the shrink film, putting it on the outside of the glass bottle, and then baking and shaping it at high temperature.

in the field of skin care products, more use is made of its good sealing characteristics to protect the internal components from external pollution, while also giving the overall image of a higher-end atmosphere.

However, not all products sold on the market can achieve the desired results. Therefore, when we select such raw materials, we must focus on several aspects including but not limited:

first of all, it depends on whether the supplier holds relevant qualification certificates and has accumulated rich experience in this market segment for a long time.

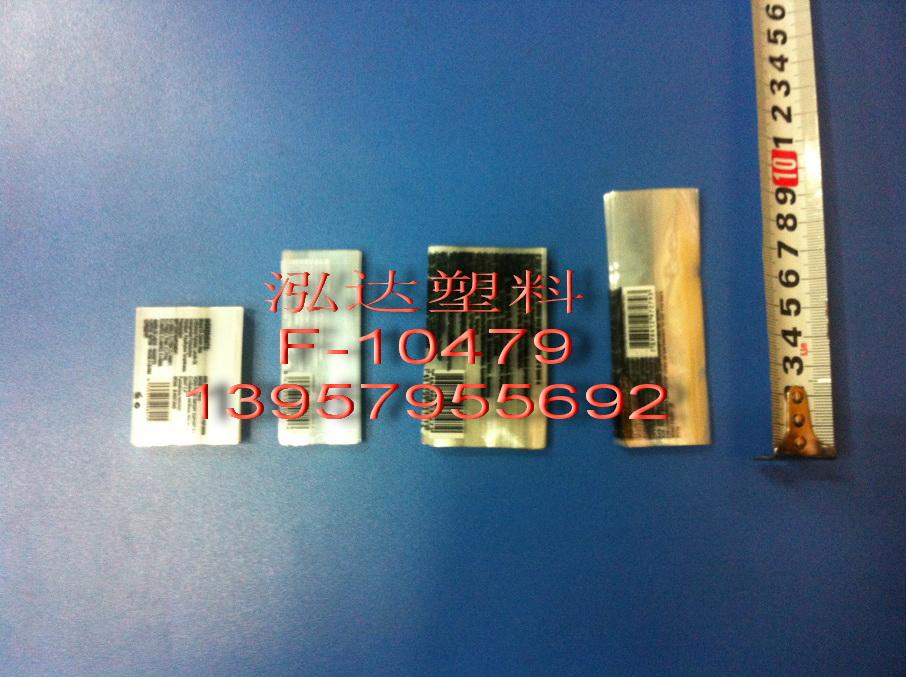

secondly, it is necessary to check whether there are obvious defects in the physical samples, such as bubble stripes, because these will directly affect the quality stability of the later processing links.

finally, it is necessary to test specific parameters such as tensile ratio elongation at break, etc. to ensure that all data are within a reasonable range so as to ensure that the final product. Expected Standard.

Facing the increasingly severe environmental protection challenges, more and more companies are turning their attention to the green and low-carbon direction. Fortunately, the development of modern technology has also injected new vitality into the color shrink film-some new biodegradable materials are gradually replacing traditional petroleum-based raw materials into actual production. This not only reduces the probability of waste of resources, but also reduces the degree of damage to the ecosystem caused by waste waste.

Many successful cases prove that the introduction of high-quality color shrink film has indeed brought significant benefits to the enterprise. A well-known mineral water brand once said that its sales volume has increased by nearly 30% month on month since it switched to a new generation of holographic colorful format. Another major household appliance retailer also lamented, "I used to worry about the damage to the outer box caused by bumping during transportation and affecting the sales experience. Now with this layer of protection, I am no longer afraid of scratching and soiling." Choosing the right partner is crucial.

All in all, color shrink film with its own superior characteristics and broad prospects for development has become one of the weapon in the contemporary business competition. If you also want to use it to start a brilliant journey may wish to act immediately!